Case Studies

OceanTools Products have been used on interesting projects and have been adapted for special situations. Please browse our case studies below. If you have a great case study using OceanTools Products please contact our Marketing Department to be featured here.

Tsunami Detection System

OceanTools won a significant contract for the design and manufacture of a 7500-metre depth rated fibre optic termination housing, backed by a subsea telecommunications cable manufacturer based in the Asia Pacific region. The OceanTools subsea design team collaborated with Subsea Connect to develop a pressure housing and cable termination solution which includes stress relief and water blocking functionality.

The deepwater housings were developed to serve as fibre optic termination housings for either telecommunications repeaters and branching units in subsea telecommunications links or as part of a tsunami early warning network. The standard product offers internal space measuring 1200mm long, with an additional mechanical termination and bend restrictor at each end, all rated for 7000m seawater deployment. The units are highly customisable including depth ratings to the client’s specific requirements and a choice of materials including stainless steel, super duplex, titanium and beryllium copper.

Following successful delivery of the first shipment of fibre optic termination housings to Indonesia, OceanTools are supporting a Tsunami Detection project in Southeast Asia. In the proposed system, similar housings are utilised for early detection of tsunami threats using sensors including seismometers and extremely accurate pressure sensors to measure earthquakes and the resultant tsunamis. The housings are linked together using telecommunications cable that carry the data great distances, from the sensors over fibre optic to shore based monitoring stations. The systems will provide the authorities the opportunity to efficiently evacuate people living in its path, therefore, reducing the number of fatalities.

Kevin Parker, Managing Director of OceanTools, stated:

“Nearly 230,000 people lost their lives in the Indian Ocean Boxing Day earthquake and tsunami of 2004. Being involved in a project that has the potential to save human lives on this scale is deeply rewarding for us. As a result of developing such technology, we now sit on a UNESCO Joint Task Force that uses our technology, not just for tsunami detection, but may also be used to monitor the effects of climate change on the world’s oceans.”

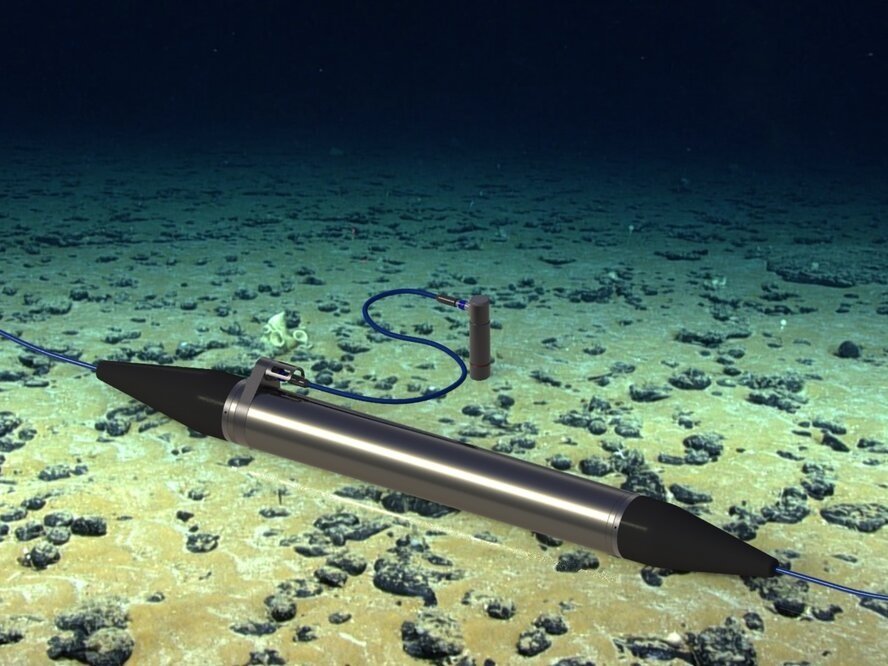

The Tsunami Detection System (TDS) is proposed for deployment subsea. The modular system will embrace our experience in subsea pressure housing design, systems integration and proven COTS environmental monitoring sensor technology.

The subsea housing will be manufactured from either super duplex or titanium. The main housing comprises polyurethane bend restrictors, cable termination, endcaps, body tube, internal brackets and the relevant internal components. If external components are used then they may be connected to the subsea housing by way of an Adaptor Plate.

The system will utilise Paroscientific pressure sensors. Units may be fitted internally or externally. If internally we shall provide a capillary ‘ring main’ with ports to the ambient seawater, as we cannot be sure of the orientation of the housing on the seafloor and a single pressure port might find itself buried in mud. The ports to the pressure sensor will be oil filled to reduce any chance of corrosion to the sensor.

The system will use temperature sensors and interferometric seismometers. These advanced devices allow the TDS to be mounted at any attitude on the seafloor. The system may incorporate a sensitive deepwater hydrophone to pick up acoustic gravity waves (AGWs) that radiate from a tsunami trigger event.

The Controller Electronics (CE) board interfaces to the various connected sensors and reads data from them. The multiple channel data multiplexer will timestamp all data, synchronised to an optional on-shore PTP time server, and present the data to an Ethernet port. A power supply unit (PSU) with a wide-ranging DC input up to 1500VDC will be used to generate local DC voltages to power the various connected sensors.

The system is offered with an optional deployment frame into which the main subsea housing and connected external sensors can be securely mounted. The frame may contain buoyancy with an uplift on each corner to help to stabilise the package during deployment and assist with preventing the package from sinking into soft sea floors.

A fibre-optic interface has been chosen that has a nominal transmission range in excess of 120km. The TDS may be connected to existing telecommunications networks or may form part of a new detection network.

Contact the OceanTools team to discuss our extensive portfolio of Underwater Technology & Engineered Solutions to support your subsea project.